Sanitary Gaskets

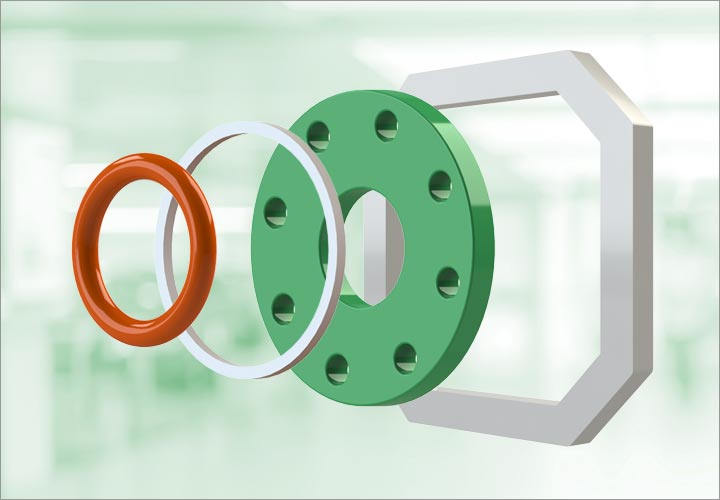

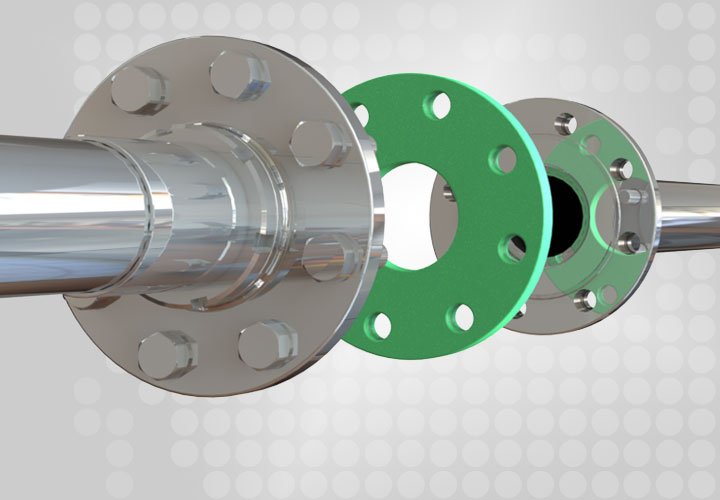

Sanitary Gaskets (or hygienic seals as they are also known) are commonplace in the design and construction of pipe couplings

The food, beverage and water processing/ handling industries are our primary market for sanitary gaskets. In terms of the demands placed upon our component material characteristics, this represents perhaps the most extreme.

Why are our sanitary gaskets so widely used?

Locations where processing and handling equipment are used by food and beverage producers can be found in large numbers. Site size will vary but production sites are often vast in size.

The pharmaceutical, bio-technology and analytical industries are also a high volume users of sanitary gaskets. Process lines have many seal clamp connections within their structure and pipework

View our range of medical O-rings online and buy with confidence from our online platform. If you can't see what you need, please feel free to get in touch, our teams are ready and available to assist you.

Medical gaskets and seals come in many material types and specifications. Our knowledge of rubber and silicone sealing solutions is extensive. Contact us to discuss your specification requirements.

Need our help to select the type of sanitary gasket you need?

Get in touch to get support from our technical support team

Application: Seal Clamp Connections

Our sanitary gaskets have the quality and longevity to prevent a sealing failure within the most demanding applications and environments

High performance materials - Applications where sanitary or hygiene seals are used require our highest performing materials. Locations such as food handling and processing require elastomers that can withstand a wide range of process media

High performance materials - Applications where sanitary or hygiene seals are used require our highest performing materials. Locations such as food handling and processing require elastomers that can withstand a wide range of process media

Quality and compliance - Our materials are designed with a quality level which can handle both CIP (Cleaning in Place) and SIP (Sterilisation in Place)

Quality and compliance - Our materials are designed with a quality level which can handle both CIP (Cleaning in Place) and SIP (Sterilisation in Place)

Reducing contamination risk through best practice - SBR-LS are recognised for precision component manufacturing. Our components support manufacturers and enable them to achieve the necessary compliance of their devices for end users

Reducing contamination risk through best practice - SBR-LS are recognised for precision component manufacturing. Our components support manufacturers and enable them to achieve the necessary compliance of their devices for end users

View our range of elastomers or get in touch to discuss your application

WRAS approved EPDM and Silicone materials are available for our range of gaskets and seals

The Water Regulations Advisory Scheme is the UK Water Industry's approval scheme

WRC-NSF is the only laboratory in the UK that carries out Water Regulations Testing for material and mechanical requirements. It covers plumbing systems, water fittings and equipment supplied, or to be supplied, with water from the public water supply.

It is illegal to install a product such as water fittings in the UK without the WRAS mark

WRAS Approved EPDM and Silicones are used in gaskets and seals that come into contact with potable (drinking) water. Therefore, our EPDM and silicone gaskets are safe to be applied in drinking fountains, faucet pipes, shower heads and the like.

EPDM rubber is completely UV stabilised making it highly resistant to ozone effects and extreme weather conditions. It is suitable for prolonged exposure to drinking water and will not deteriorate when submerged. This makes it ideally suited for gasket sealing applications.

For full details on our compliance and certification, please visit our Quality page...

For full details on our compliance and certification, please visit our Quality page...