What is a Check Valve?

A check valve is designed to allow the flow of either liquid or gas one way.

Check valves, are also known as non-return or one-way valves, and are often used as pressure relief valves. The basic design of a check valve inhibits backflow.

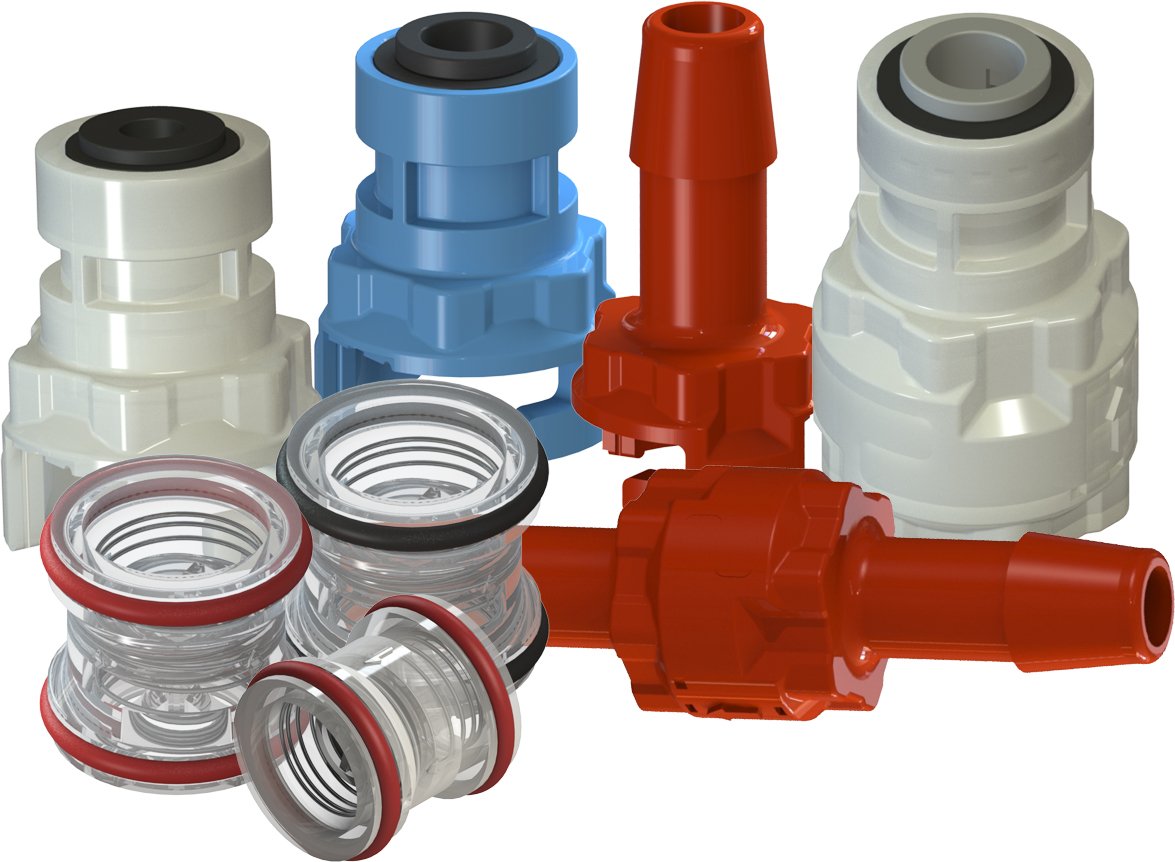

As a specialist supplier of miniature components, The West Group product portfolio contains a comprehensive range of check valve options. Depending upon the type of Check Valve chosen the operation of the check valve differs from type to type.

The West Group Check Valve types are extensive, these include Floating Disk, Diaphragm, Duckbill, and Poppet.

The West Group strength lies in our ability to support customers whom are supplying into the medical and scientific markets. We provide many specification and material options specifically designed to meet the standards and compliances required by the healthcare industry.

How does a Check Valve work?

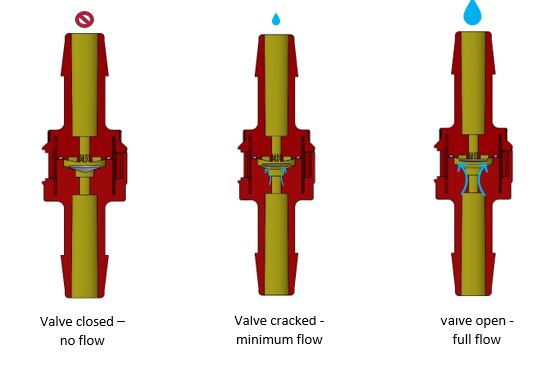

Because of their simple design, check valves generally operate without automation or human interaction and instead rely on the flow velocity (upstream pressure) of the liquid or gas to open and close. This means they generally do not have a method of external operation, like a handle or lever. The minimum upstream pressure required to open the valve is called the “cracking pressure”. Check valves are designed for a specific cracking pressure, and depending on the size and style of check valve, the cracking pressure can vary to suit the application. Cracking pressures from 0.1 psi (5mmHg or 70mmH2O) to 10 psi for applications are not unusual. The degree of opening on a check valve is determined by the flow rate. The higher the flow rate, the more open the valve will be until it reaches its maximum, fully open position.

Types of Check Valves

We have many types of check valves available on Eox and many configurations for our modular valve. Please see below to read about how are types of check valves work

Floating Disk

These types check valves are almost always normally open. A self-centering flexible elastomer disc is the working part of this type of diaphragm check valve. The valve body keeps the disc centered over the seating area or sealing surface of the valve. The sealing surface is on the inlet side of the check valve body. It has a fine, smooth surface that is usually concave or curved back towards the inlet port. There is an opening at its centre. Backflow causes the flexible elastomer disc to lie down across the curved sealing surface. This closes the opening to the inlet port. The closed check valve prevents upstream flow back through the inlet port. A floating disc diaphragm check valve has a particular design on the outlet side of the valve body. Here there is usually some sort of two-level valve seat with built in channels. Positive flow towards the outlet or exit port causes the disc to lie against this seat. The media then flows around the disc, through the channels and out through the exit port of the check valve.

Diaphragm

These types check valves are almost always normally closed. Diaphragm types rely upon a formed elastomer shape sealing against a surface in the flow path with enough stiction to overcome any backflow pressure that may exist in the system. The membrane shifts within the housing as the forward pressure increases until it is greater than the backflow pressure. When this differential occurs the diaphragm either compresses or bends to allow the valve to open and the media to flow around the diaphragm and out through the outlet.

These types check valves are almost always normally open. A self-centering flexible elastomer disc is the working part of this type of diaphragm check valve. The valve body keeps the disc centered over the seating area or sealing surface of the valve. The sealing surface is on the inlet side of the check valve body. It has a fine, smooth surface that is usually concave or curved back towards the inlet port. There is an opening at its centre. Backflow causes the flexible elastomer disc to lie down across the curved sealing surface. This closes the opening to the inlet port. The closed check valve prevents upstream flow back through the inlet port. A floating disc diaphragm check valve has a particular design on the outlet side of the valve body. Here there is usually some sort of two-level valve seat with built in channels. Positive flow towards the outlet or exit port causes the disc to lie against this seat. The media then flows around the disc, through the channels and out through the exit port of the check valve.

Diaphragm

These types check valves are almost always normally closed. Diaphragm types rely upon a formed elastomer shape sealing against a surface in the flow path with enough stiction to overcome any backflow pressure that may exist in the system. The membrane shifts within the housing as the forward pressure increases until it is greater than the backflow pressure. When this differential occurs the diaphragm either compresses or bends to allow the valve to open and the media to flow around the diaphragm and out through the outlet.